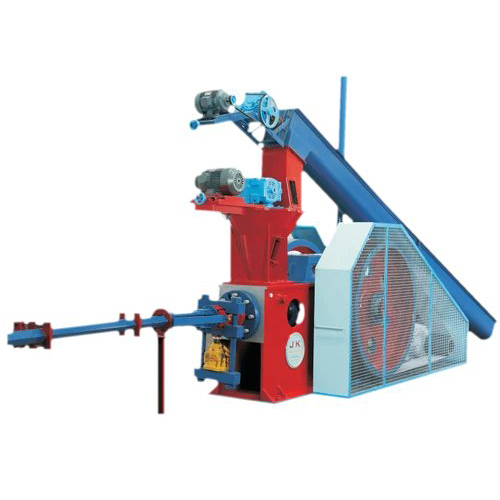

Biocoal Briquetting Machine

Product Details:

- General Use produce white coal

- Production Capacity 1200-2000 (depends on raw material) Kg/hr

- Product Shape Cylinder

- Weight (kg) 8500 (approx.) Kilograms (kg)

- Type Briquette Machines Briquette Press Machine Wood Chips Briquette Machine

- Computerized No

- Automatic Yes

- Click to View more

Biocoal Briquetting Machine Price And Quantity

- INR

- 1 Plant

Biocoal Briquetting Machine Product Specifications

- produce white coal

- AC Motor

- Constant Pressure

- Yes

- Cylinder

- 1200-2000 (depends on raw material) Kg/hr

- Water Cooling System

- No

- 8500 (approx.) Kilograms (kg)

- Briquette Machines Briquette Press Machine Wood Chips Briquette Machine

- No

- Low Consumption Energy Saving High Efficifiency Automatic Feeding System Automatic Discharging System Compact Structure

- 415 Volt (v)

Biocoal Briquetting Machine Trade Information

- Letter of Credit (L/C) Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque

- Per Month

- 45 Days

- All India

Product Description

Biocoal briquetting machine with 1200 kg/hr to 2000 kg/hr capacity is integrated with DC motor. In spite of it being 8500kg heavy, this equipment deserves credit for its automatic operation and an advanced water cooling system. A high temperature indicator is one of the standard components. This machine is characterized by its high pressure based mechanism, high service life, robust construction, ergonomic look, and low maintenance costs. This machine is designed to convert agricultural waste and forestry waste into biochar/bio briquettes. In terms of economy and environment, biomass briquetting is the best renewable source of energy.

The importance of energy and its sources is well known to us all. The development of every economy relies on energy. We are facing an increase in energy demand and a limited supply of energy sources. There is a global energy crisis with fossil fuels such as petrol, kerosene, LPG, etc. A huge gap exists between supply and demand. A solution that fills this gap is renewable energy. It is a concept that many developed countries have adopted and embraced, and have kept their natural resources for energy and fuel.

Its main objective is to produce bio-coal from waste materials. Using a briquetting plant, we can utilize the wastes and produce briquettes which produce energy at low cost. The waste can be agriculture waste or forestry waste, sycg as coffee husk, groundnut shell, rice husk, jute waste, coir pith, tea waste, tree bark, wild grasses and shrubs, etc,

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Briquetting Machine' category

|

JAY KHODIYAR MACHINE TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free