Showroom

Biomass can be processed and compressed into briquettes using briquetting machine. Any organic waste material can be processed in this machine.

Once the organic waste is processed, it is the time to compress it into briquettes. Briquetting press machines can be employed for this job.

Turbo briquetting dryer is a vertically aligned industrial dryer that takes an open, small floor space for installation. As the very name implies, this machine is used for drying material used for making briquettes.

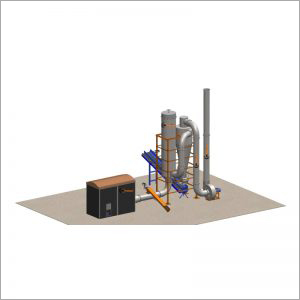

Install a briquetting plant in your factory if you want to produce fuel out of waste. This plant removes moisture from the material and compress the waste material into briquettes.

The offered white coal Plant is made available by us for use in the various places and is very efficient. It is very effective and suitable for use in the various places. The plant is highly durable.

We, Jay Khodiyar is known for its technologically enhanced White Coal Project among all models as it is designed to give maximum output, hold innovations like Special Sensor System and Special Siren System along with making it reasonable and higher demands in market.

The Briquetting System manufactured by us that start out our journey of excellence and innovation is Briquetting Machine. This machine is supported by Hammer mill to crush the raw material before it is used to produce bio-mass briquettes or white coal. It is widely appreciated for its performance and quality. Various type of raw material such as forest waste, agriculture waste can be used to make biomass briquettes.

Our company is providing Wood Chipper Machine with best quality and long life products. It is basically used for cutting & chipping various raw material into desired size according to the customer needs. The crusher cut the material into small pieces which helps to make material portable.

|

JAY KHODIYAR MACHINE TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free